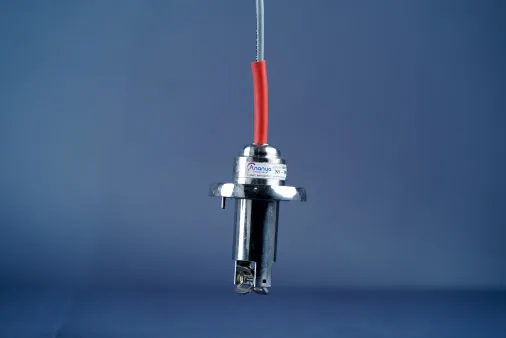

General Description

We are Manufacturer, Supplier Of NS-100 Flow Sensor. Our Setup Situated in Pune, Maharashtra, India.

NS-100 is a Stainless steel paddle wheel type flow sensor suitable for all industrial / commercial applications. It is most durable, compact & advance type paddle wheel flow Sensor. It is corrosion resistant featured in paddle, can be installed in wide range of pipe sizes fitting like threated end / stubend with ms flange end / SS welded flange end / saddle & etc.Silent Features

- Economical & Accurate

- Easy to install & maintain

- Wide range of installation fittings

- Practical no pressure drop

- Heavy duty industrial application

- Suitable for muddy liquid

- 4 blade impeller for best performance

- Linear, repeatable & constant output

- Can be used directly to PLC or datalogger

- Individually calibrated with fitting for K factor (ml/pulse)

- High amplitude output signal from sensor eliminates needs of re-transmission upto 100 meter

Application

- Agriculture

- Boiler Condensate water

- Beverages & Food

- Chemicals & Pharmaceuticals

- Concrete batching plant & construction

- Filtration systems

- Power

- Textiles

- Water treatment

- Oil

Line size flow range chart

| Pipe Size (NB) | 15 | 25 | 40 | 50 | 65 | 80 |

|---|---|---|---|---|---|---|

| Min Flow M³/Hr | 0.2 | 0.8 | 1.9 | 3.5 | 5.8 | 7.5 |

| Max Flow M³/Hr | 2.1 | 8.0 | 19 | 35 | 58 | 75 |

| Pipe Size (NB) | 100 | 125 | 150 | 200 | 250 | 300 |

| Min Flow M³/Hr | 14 | 22 | 31 | 56 | 87 | 126 |

| Max Flow M³/Hr | 140 | 220 | 310 | 560 | 870 | 1260 |

Range details

| Pressure | Up to 15 kg/cm² |

| Viscosity | Up to 20 CP |

| Temperature | 0 to 50°C |

| Velocity | 1 to 5 m/s |

| Accuracy | ± 2% of full scale |

Material Details

| Sensor pipe | SS 304 |

| Paddle | SS |

| Pin | WC |

| Gasket | PTFE |

| Bush | PEEK |

| IP | 65 |

Electrical Details

| Output Signal | PNP |

| Power Supply | 12-24 VDC |

| Cable Type | 3 Core PTFE / PVC coating |

| Cable length | 5 meters standard |

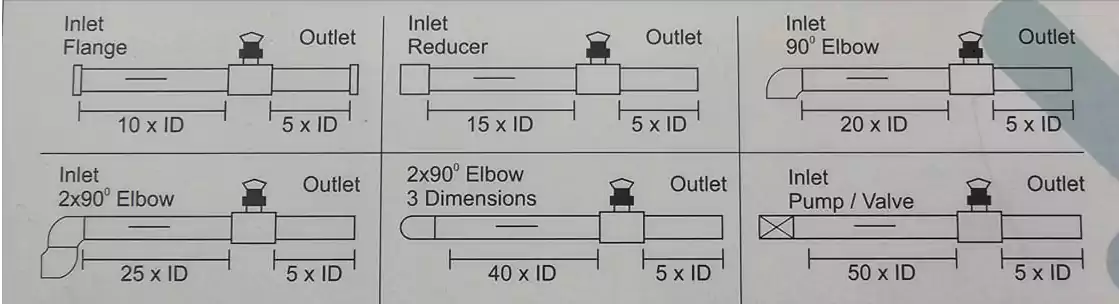

Inlet and outlet distances that must be maintained as per guidlines formula chart

Note:

- In Vertical piping only Upstream flow is recommended

- Flow meter + sensor + fitting should be installed before valve

- Use a filter or Y type strainer is must for best result.