General Description

We are Manufacturer, Supplier Of Flowscale - 230 VAC. Our Setup Situated in Pune, Maharashtra, India.

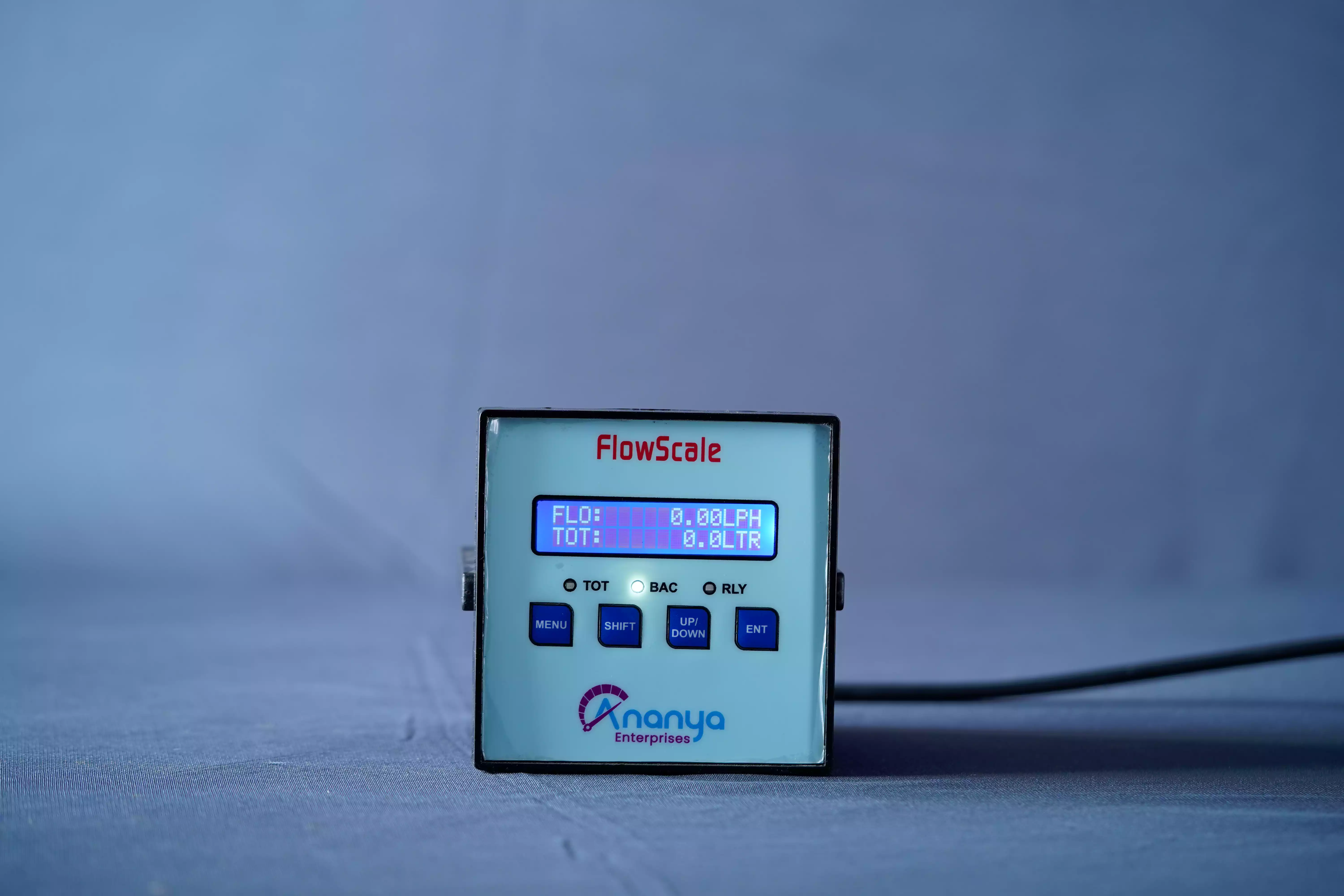

Flowscale – 230 VAC flow rate indicator are controller based unit with high resolution LCD display. Flowscale – 230 VAC is a digital type flow rate indicator for measuring specific type of liquid function of totalizer, Batch controller, RS 485 output, 4–20 mA output & relay, Flow rate in LPH / LPM / GPM & M³ / Hr & total reading in LITRES / M³ & GALLON. Flow meters can be mounted on panel or field. By using front keys we can view programme in display with different parameters and also indicates operating modes on display key board with bright OLED's, the pulse generated is transmitted and converted into a volumetric measurement.Silent Features

- Indicates operating modes on display keyboard with bright OLED'S

- Flow indicator all function are password protected

- Front keys for calibration

- Easy to install & maintain

- Single relay for flow control operation

- Economical & efficient

- High performance & durability

- Easy to handle keys for view/changes setting

Application

- Agriculture

- Boiler condensate water

- Beverage & food

- Chemicals & Pharmaceuticals

- Concrete batching plant/ construction

- Filtration systems

- Oil

- Power

- Textiles

- Water treatment

- Sewage water

Material Details

| Box | ABS |

| IP | 55 |

Electrical Details

| Power supply | 230 VAC |

| Display | 16 x 2 LCD |

| Cable Length | 1 meter Standard |

| Cable type | 2 Core PVC |

| Input | From NS-50 / 100 / 150 sensor (Ananya make) |

Flow Indicator Function

| Mounting | Field / panel |

| Flow measurement unit | LPH / LPM / GPM / M³ / Hr |

| Function | Totalizer + Batch controller + Flow Rate + RS 485 output + 4-20 mA output + Relay |

| Meter size | 96 x 96 x 85 mm |

| Meter Cutout size | 92 x 92 mm |

| Flow total reading | Liters / Gallon / M³ |

Calibration

Scale factor : The K factor is a constant that converts the number of pulses or signals generated by a flow meter in to a meaning full flow rate.

New scale factor = Measured Qty X Existing scale factor / Display Qty

Note:

- In Vertical piping only Upstream flow is recommended

- Flow meter + sensor + fitting should be installed before valve.

- Use a filter or Y type strainer is must for best result.

- Assure proper connection of mains, wrong connection may damage the indicator.

- Avoid noise interference due to extending the cable use proper insulation.

- Do not pass sensor cable parallel to power cable, if it is pass then sensor cable through noise protected tray.

- flow range should match as per given our line size chart.